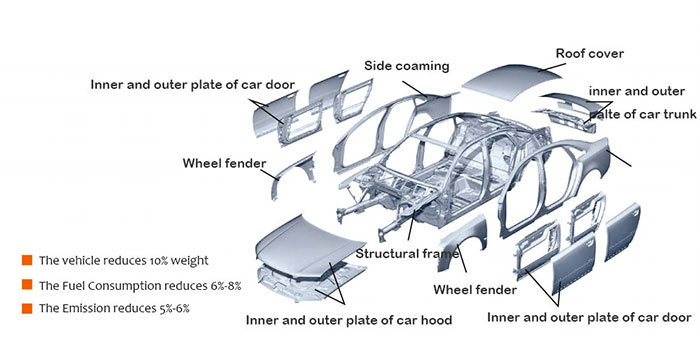

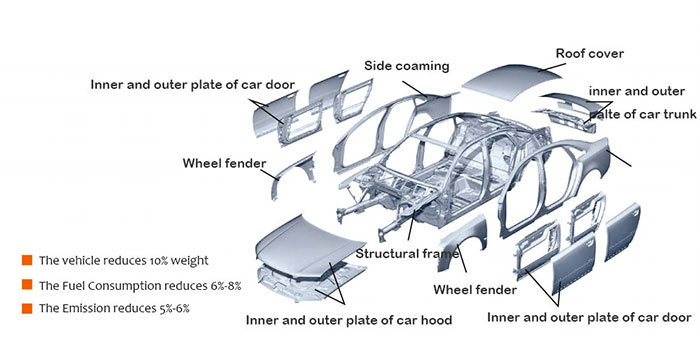

With the development of lightweight of automobile, the aluminum sheet, with low density, high specific strength and corrosion resistance, has become the best choice for replacing the steel in the automotive industry. there are 5000 series and 6000 series for the aluminum alloy of automobile body plate, compared with ordinary steel plate, its yield strength and tensile strength are better, and its corrosion resistance and oxidation resistance.

In the application of aluminum in automobile, the moulding aluminum plate can make the automobile energy saving low consumption, safe and comfortable and the relative heavy load capacity, etc. The use of thin aluminum plates in the automotive transmission system of the 5 series and 6 series is more than the aluminum foil and aluminum foil products needed by the automobile industry. The main alloy brands include 5182, 5083, 5754, 5052, 6063 and 6082 aluminum plates. According to different alloy properties, it can be applied to truck chassis, tank body, passenger car body, body body and radiator.It has good corrosion resistance, good welding performance, good process performance (easy extrusion forming) oxidation coloring and other properties.

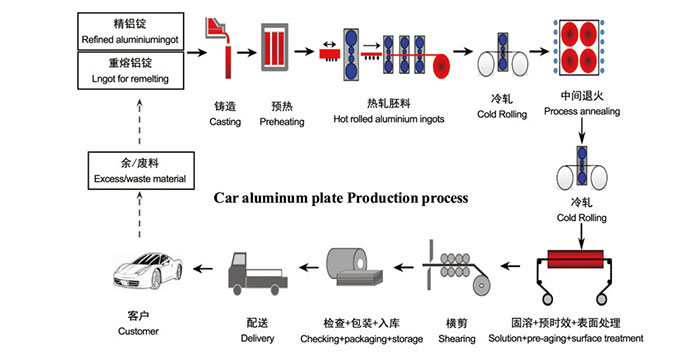

Mega aluminum is equipped with word-class level casting and melting line ,hot rolling mill, cold rolling mill, EDT equipment, air cushion floating furnace, passivating equipment ,pre-aging equipment and extrusion line,The main alloy is 5754,5182,6061,etc.

|

The ourter plate of car |

6011-T4, 6016-T4 |

|

Structural frame |

6082 – T651 |

|

Cover, shock absorber and decoration plate |

5052 – H34 |

|

Car welds parts |

5083 – H112;5083 – H116;5083 – H321 |

|

Inner plate, bearing floor and control panel |

5182 – H321;5182 – H34 |

|

Door, bearing floor and inner plate |

5754 – H112 |

Specification

|

Alloy |

Temper |

Thickness(MM) |

Width(MM) |

|

5182 |

H16/H111 |

0.5-3.5 |

1200~2650 |

|

5754 |

|

6016 |

T4/T4P |

|

6101 |

T63/T64 |

0.5-8 |

1200-2600 |

Mechanical properties

Alloy

|

Temper |

Yield Strength

Rp0.2(Mpa) |

Tensile Strength

Rm(Mpa) |

A80 Breaking Elongation(%)

|

Ag Uniform

Elongation(%) |

R Plastic strain ratio |

N Strain hardening exponent |

Rp/Rm Yield Tensile ratio |

%IACS

Electrical Conductivity |

|

5182 |

O/H111 |

120-160 |

≥270 |

≥26 |

≥22 |

≥0.6 |

≥0.26 |

≤0.6 |

- |

|

5754 |

H32 |

100-130 |

210-240 |

≥22 |

≥19 |

≥0.6 |

≥0.25 |

- |

- |

|

6016 |

T4/T4P |

85-130 |

205-240 |

≥24 |

≥20 |

≥0.6 |

≥0.26 |

≤0.55 |

- |

|

6101 |

T63 |

≥150 |

≥185 |

- |

- |

- |

- |

- |

≥56 |

|

6101 |

T64 |

≥55 |

≥105 |

- |

- |

- |

- |

- |

≥59.5 |

At present, we have developed a mature product of

5182 alloy plates for the car door, car hood and the front and rear wing of the car. The stamping effect of Mega aluminum alloy 5182 is good and no crack.

5182 aluminum alloy, at present, the thickness range is 0.15-600mm, and the width range is 20-2600mm (according to the customer's demand).

The lightweight aluminum alloy products developed by Mega aluminum for automotive chassis and car storage tanks are 5083, 5754, 5052 aluminum plate. The 5083 and

5052 aluminum plate in these auto parts is the most widely used.

The automobile wheel hub is mainly made of

6061 aluminum plate. 6061 aluminum alloy is very important product, developed by Mega aluminum. We have very mature technology. Thickness range: 0.30-600mm, width range: 150-2600mm.

As a result, the company has invested a lot of energy in the lightweight application materials, and has developed aluminum foil products that are suitable for each part.

INSPECTION CERTIFICATE (contract no.: MAL-20170315146)

Specification: 5182-O, 1.2X1040X2000mm

Standard: BS EN 485-3-2003,BS EN 485-2-2007,BS EN 573-3-2009

1. Chemical Composition

|

Element (%) |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Each |

Total |

Al |

|

max |

0.20 |

0.35 |

0.15 |

0.50 |

5.0 |

0.1 |

0.25 |

0.10 |

0.05 |

0.15 |

REM |

|

min |

|

|

|

0.20 |

4.0 |

|

|

|

|

|

|

|

Real pro |

0.068 |

0.164 |

0.0788888 |

0.213 |

4.666 |

0.02 |

0.031 |

0.018 |

|

|

Rem |

2. Mechanic Property

|

Property |

Rm(MPa) |

Rp0.2(MPa) |

A50(%) |

n |

r |

|

Real |

268(0°)

264(45°)

263(90°) |

118(0°)

116(45°)

116(90°) |

24(0°)

28(45°)

27(90°) |

0.32(0°)

0.34(45°)

0.32(90°) |

0.945(0°)

0.889(45°)

0.823(90°) |

3. Tolerance & Coil Quality

Thickness(mm)

(mm) |

Width(mm)

(mm) |

Length(mm)

(mm) |

Test Results

(Coil Quality) |

|

±0.01 |

-0+1 |

-0+2 |

Qualified |