5052 Aluminum sheet is Al-Mg alloy, cold forming has good processing performance, processing performance, good corrosion resistance, rust proof aluminum alloy 5052 is a most widely used, this alloy has high strength, especially the anti fatigue strength, ductility and high corrosion resistance, in the semi-cold hard plastic is good, the

5052 H19 aluminum sheet is used for the the cover without internal pressure, do first oxidation treatment to improve coating adhesion and corrosion resistance, both sides painted after the tank cover forming processing, our 5052 alloy lid material is with good surface quality, stable performance.

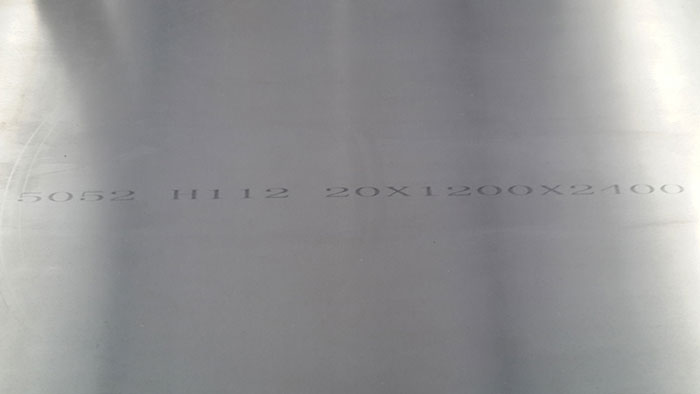

The specification of

5052 aluminum sheet

|

Alloy |

Temper |

Thickness

(mm) |

Width

(mm) |

Length

(mm) |

Typical application |

|

5052 |

O,H12,H14,

H16,H18,H19,

H22,H24,H26,

H28,H32,H34

H36,H38,H111,

H112,H114,H 116,H321 |

0.15-500 |

500-2800 |

500-16000 |

marine sheet metal parts, chemical oil storage device |

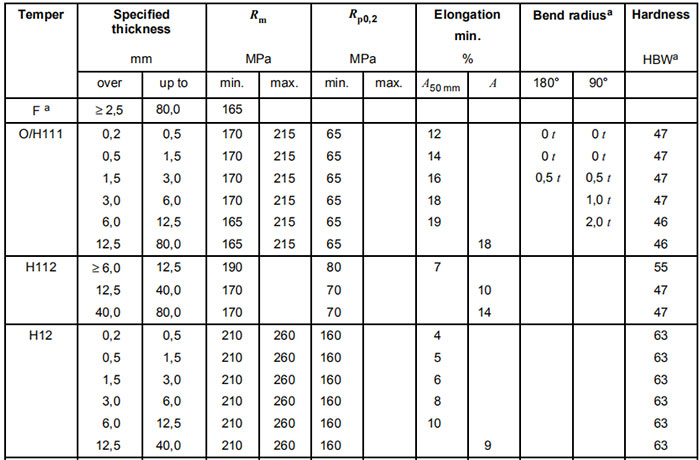

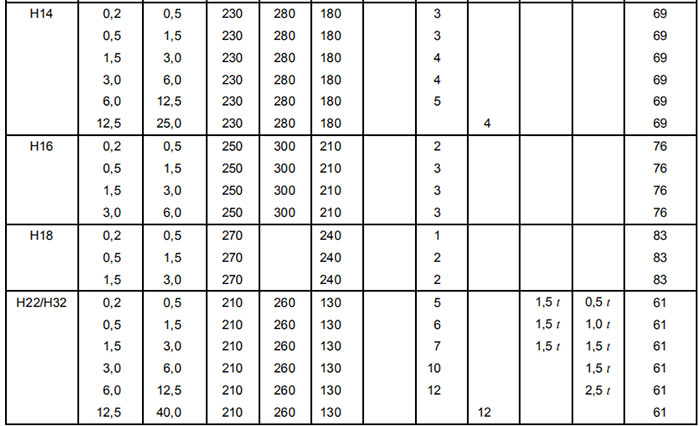

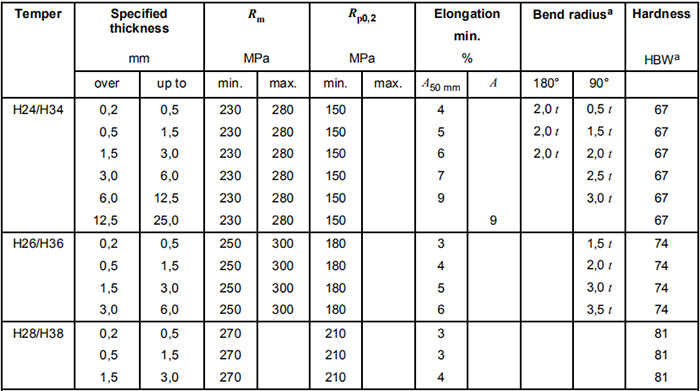

Alloy EN AW-5052 [Al Mg2,5]

Performance advantage

1.

5052 Aluminum Alloy plate sheet has high plasticity, corrosion resistance, suitable for use in marine environment.

2. the surface of the

5052 aluminum plate is without peeling, bubble, surface rough and local mechanical damage.

Application of 5052 aluminum sheet

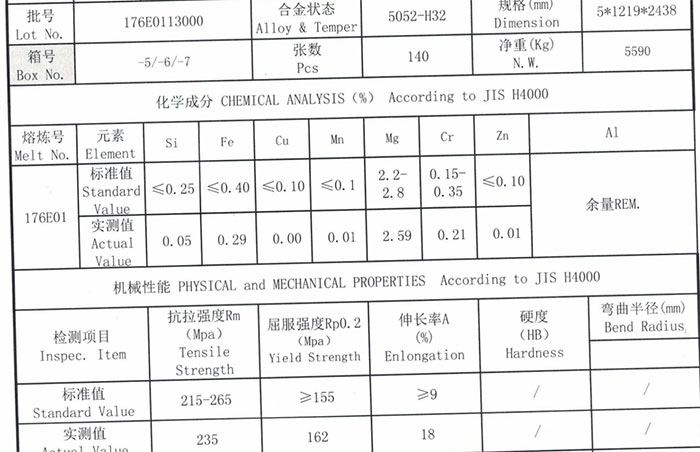

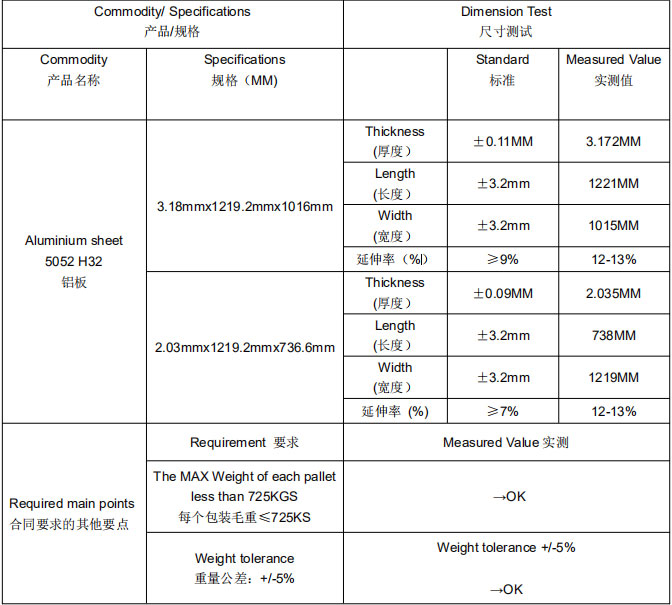

The test report of 5052 aluminum sheet

1. Size: 1219*2438*5mm for one of our Korea customer

2. Size: 3.18*1219.2x1016mm for one of USA customer

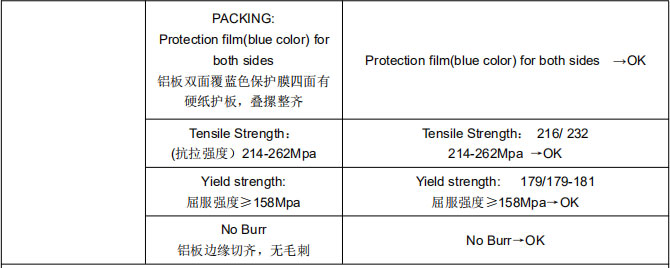

The package of 5052 aluminum sheet

1. the paper or cover film between aluminum sheet to ensure the surface of the aluminum plate without intact or scratch

2. plastic or paper package to moisture-proof and waterproof, guarantee the aluminum plate clean with no dirt in transit, each package has moisture-proof desiccant.

3. Reinforce the wooden brackets with steel straps to avoid collision during transportation, so as to ensure that the geometry of the aluminum plate is unchanged

4. Fumigation wooden pallet