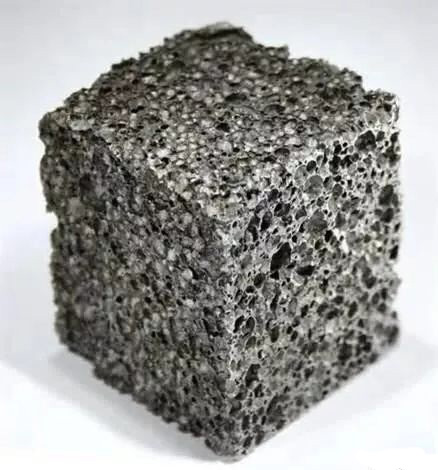

Foamed aluminum panel is a porous material in which numerous bubbles are distributed in a metallic aluminum matrix. The performance of

foamed aluminum mainly depends on the pore characteristics distributed between the three-dimensional framework, ie, the shape and distribution of the pores, including the type of pores (through-hole or closed-cell), the shape of the pores, the distribution of the pores, the pore structure (pore size, pores) Rate, proportion, etc.).

1. Physical properties

The most obvious feature of

foamed aluminum panel is its light weight and low density, which changes with the change of the hole. The specific gravity is only 0.1-0.6 times that of the same volume of aluminum, but its firmness is more than 4 times higher than that of the foam.

foamed aluminum material is much less conductive than solid aluminum materials and, on the contrary, resistivity is much greater and is a poor conductor of electricity. The thermal conductivity of

foamed aluminum is much less than that of solid aluminum, which is about 0.1-0.2 times that of solid aluminum. In addition,

foamed aluminum panel also has the characteristics of large rigidity, non-flammability, non-oxidation, hard aging, good weather resistance, good recyclability, and so on.

For devices subject to bending loads, the materials used should have a high specific strength, with specific strength values for

foamed aluminum material and several common structural materials (aluminum, steel) (foam aluminum:aluminum:steel=5:2.5:1) By comparison,

foamed aluminum panel has a high specific strength. Experimental studies have shown that proper heat treatment can increase its specific strength. Therefore,

foamed aluminum panel can be used in large bending load devices.

2. Mechanical properties

As with other porous materials, the elastic modulus, shear modulus, and elastic limit of

foamed aluminum decrease exponentially with increasing porosity.

(1) Tensile Strength Aluminum foam has low tensile strength, almost no elongation, and shows semi-brittleness. The experiment found that the pore size has a certain influence on its tensile properties. When the relative densities are the same, the tensile strength with a small pore size is higher than the pore size.

(2) Compressive strength Although the tensile strength of aluminum foam is very low, its compressive strength is higher. The

foamed aluminum compressive stress-strain curve can be divided into three regions: the linear elastic zone, the yielding plateau zone, and the densification zone. The compressive stress-strain curves of aluminum foams with different pore diameters are basically similar in shape. The difference is mainly reflected in the height of the plastic platform. It was found that the pore size and the height of the plastic platform are not a simple linear relationship, but are at a certain aperture. The lower plastic platform is the highest. From the relationship between the compressive strength of aluminum foam and its density and compressibility, it can be seen that the density increases and the compressive strength increases.

3.Energy absorption characteristics

Porous structural materials can be used as energy absorbing materials. Materials with small unit mass and high energy absorption capacity have a greater role.

Foamed aluminum sheet has a small mass and high strength, so

foamed aluminum has a high energy absorption capacity.

In the compression process,

foamed aluminum sheet has a high and wide stress plateau that can absorb energy through strain under a substantially constant stress. The energy absorption capacity is determined from the area under the stress-strain curve, so the higher the yield platform is, the greater the energy absorption capacity is.

The pore size has a certain influence on the height of the yielding platform, so a suitable pore size can be found so that the yielding platform is higher to increase its energy absorption capacity. In addition, its energy absorption capacity varies non-monotonically with porosity and has the greatest energy absorption capacity at a certain porosity.

4.Damping performance

The damping property of a material refers to the ability of the material to irreversibly convert mechanical vibration energy into heat energy for internal reasons. With this ability of materials, unwanted noise and vibration can be reduced.

According to Zener's classical theory, one of the important ways to improve the damping properties of metal materials is to try to maximize the interaction between defects to obtain the maximum linear damping, or to introduce mechanical amplification mechanisms to the materials to obtain higher Nonlinear damping.

The porous material apparently conforms to the organizational characteristics of the highly-damped material, and experiments have demonstrated that the presence of holes can play an important role in the damping response of certain non-metallic or metallic materials.

As a kind of macroscopic porous material,

foamed aluminum consists of metal skeleton and pores. The organization is extremely uneven and the strain strongly lags behind the stress. The compressive stress-strain curve contains a very long plateau, so it is a type with high energy absorption. The characteristic lightweight high damping material has a considerable application prospect in the fields of noise reduction and vibration damping. Experimental study found:

(1) When the pore size is fixed, the internal friction of foam aluminum increases with the increase of porosity;

(2) When the porosity is constant, the internal friction of foam aluminum increases with the decrease of pore size.

(3) The internal friction of foam aluminum is closely related to the strain amplitude and increases with the amplitude;

(4) The internal friction of foam aluminum has no significant relationship with the change of frequency in the low frequency range.

5. Sound absorption performance

Foamed aluminum sheet is especially aluminum foams with through-holes. When sound passes through foamed aluminum, acoustic waves are also a type of vibration. Scattering, interference and diffuse reflection can occur inside the material. The sound is absorbed in the pores of the foam and the internal skeleton vibrates. Part of the sound energy is converted into heat energy and consumed by heat transfer, which plays a role in sound absorption. Therefore,

foamed aluminum has a good sound absorption capability.

The sound absorption performance is measured by the sound absorption coefficient. The greater the sound absorption coefficient is, the better the sound absorption performance is. The sound absorption performance of the foam aluminum mainly depends on the pore characteristics, and the sound absorption performance of the through hole is good. The smaller the hole, the better the sound absorption performance.

Application of foam aluminum

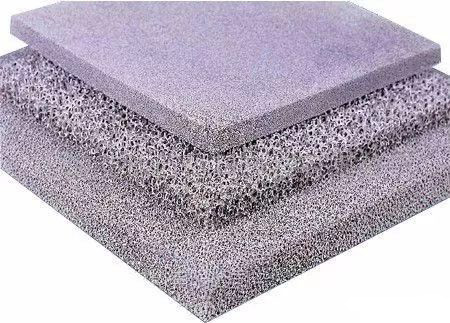

1. Building materials

Due to its lightweight per unit volume, soundproofing, anti-vibration, fire-resistant, non-flammable, thermal insulation, etc.,

foamed aluminum can be used to build non-load-bearing interior walls, partition walls, doors, ceilings, and exterior decorative materials. It can also be used in any building that requires air tightness and good ventilation performance.

When it is used for surface decoration, it can also be used for the effect of foam plastics, marbles, and other decorative materials. It is suitable for the construction of so-called mobile floors in the case of frequent changes in the distribution piping of electronic computer rooms, physical and chemical laboratories, etc. . For this, honeycomb structure materials, die-cast materials, etc. are currently used, but aluminum foam can be used instead.

The exterior of large buildings, at the top, is to avoid the use of heavy materials, and

foamed aluminum sheet is just right for this need. This is not only light weight, but also allows the appearance of design freedom. When there is a special requirement for strength, foamed aluminum can be used.

2 .decorative materials

Foamed aluminum panel can be used as a decorative material inside or outside the building and can be made of any material such as stone, marble, wood, and glass. Because the sculptural objects, statues, and other objects created with it are large and light, it is extremely easy to carry.

3. soundproof material

It can effectively use it as a wall to adjust the sound effects of radio, music, lecture halls, and theaters. In the industrial sector, it is suitable as a platform for soundproofing and sounding machines in power generation rooms, engine test rooms, and airports. In daily life, it is used as a structural part for phonographs, stereo cameras, soundproofing for interior coolers, soundproofing parts for hotels, and the like.

4 .anti-vibration material

For use as a car bumper and other incidental parts to slow down the collision for safety purposes,

foamed aluminum panel is the best material. Contrary to this, it can also be used as a gentle vibration material for collisions with devices along the road.

Vibration-proof materials such as transportation and installation of heavy and valuable objects are ideal. This material was used under the landing gear when Apollo 11's LM landed on the lunar surface. Adapt to the lug on the lunar surface when landing, and mitigate the vibration with the destruction of

foamed aluminum. Also suitable as a backing material for valuables.

5. Profiles

Since the foamed styrene model and other large models used at high temperatures must be lightweight in operation, this material can be used. For prototype cars and other large models, honeycomb structures and other materials have historically been used, but they have the disadvantage of high cost, while aluminum foam is inexpensive and easy to shape, and is suitable for repetitive trials when the mold shape changes.

6. Application in the automotive industry

The excellent performance of foam aluminum determines that it has a wide range of applications and broad application prospects. Especially in the automotive industry, aluminum foam is considered to be a promising material for the future of automobiles and other transportation vehicles.

With foamed aluminum components, the rigidity of the car's frame is enhanced. About 20% of body structures in automobile manufacturing can be made of foamed aluminum. Parts made of foam aluminum for a medium-sized passenger car can weigh about 27.2 kg. At the same time, the structural system can be simplified, and the number of components can be reduced by at least 1/3. The cost of the car.

Aluminum foam material is a good energy absorber, the energy absorbed per unit volume can reach 6-9MJ, a strong energy absorption capacity shows its superiority as a car bumper buffer material. The use of suitable elements made of foamed aluminum in the impact zone of the vehicle can control the deformation of the maximum energy consumption. For example, in the hollow steel or aluminum housing filled with foamed aluminum, these components can have good deformation behavior during loading.

The

foamed aluminum sheet is used in the deformable material before and after the passenger seat of a car to improve safety.

Foamed aluminum is heat-resistant and flame-retardant. At the same time, it will not release toxic gases when it is heated. Therefore, the use of

foamed aluminum panel instead of foamed plastic or foamed resin materials in transportation vehicles can increase the service life and reduce maintenance. Eliminating the harmful gases produced by traditional materials in vehicle accidents, greatly reducing the losses and casualties in traffic accidents, and also playing an environmental role.