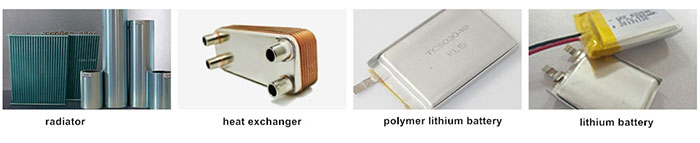

The 3003 is a typical aluminum alloy Al-Mn, this material has good form-ability, good corrosion resistance and weld-ability. It is widely used for power battery shell,storage tank, cooking utensils, food warehouse transport equipment, sheet metal pressure vessels and piping, etc.

Performance advantage of 3003 aluminum sheet

1. High excellent rust resistance

2. The

3003 aluminum sheet plate has excellent forming characteristics, high corrosion resistance, good weld-ability and conductivity, strength higher than 1000 series aluminum sheet.

3. The

3003 aluminum sheet has smooth surface, good plasticity, pressure resistance

4. It is the the best choice for power battery shell, with impact resistance, no easy to break and leak

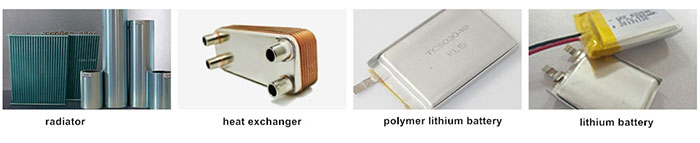

The application of 3003 aluminum sheet

The application of 3003 aluminum sheet

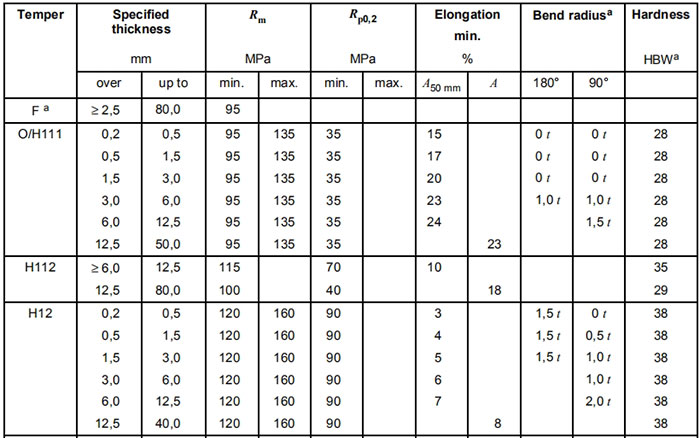

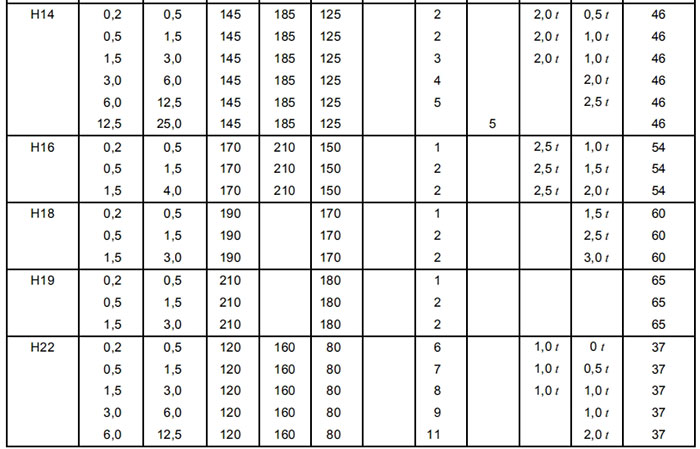

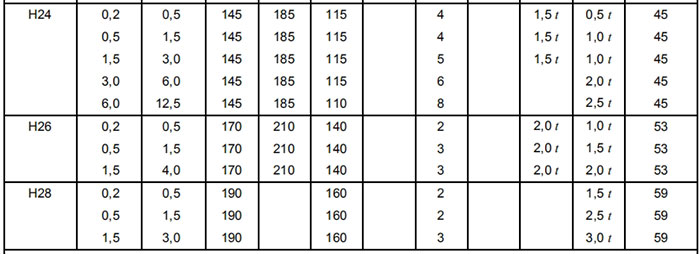

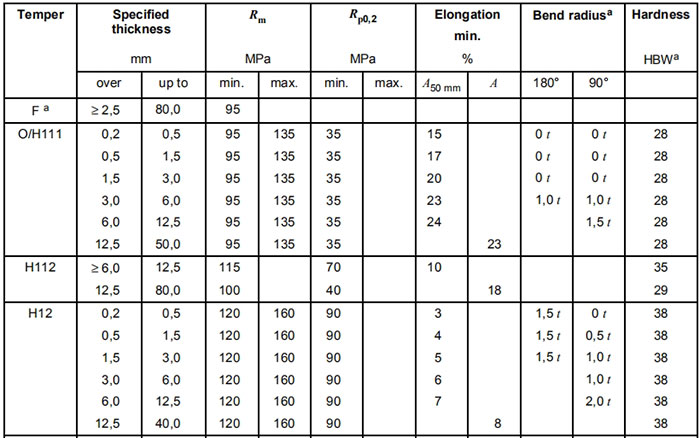

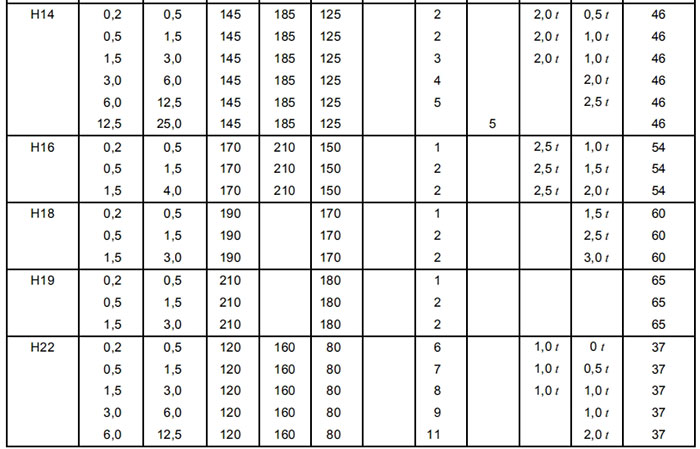

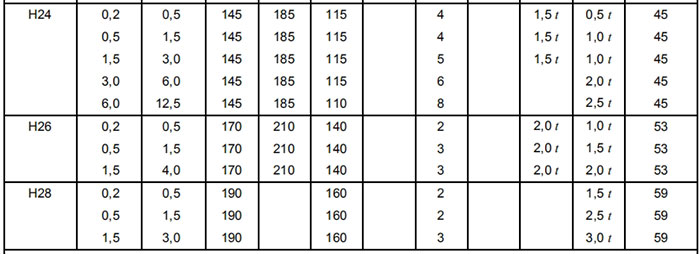

The specification of 3003 aluminum sheet

|

Temper |

O,H12,H14,H16

H18,H19,H22,H24

H26,H28,H32,H34

H36,H38

|

|

Thickness |

0.2-5mm |

|

Width |

100-2800mm |

|

Length |

500-16000mm |

|

Surface treatment |

Mill finish, color coated |

|

Type |

Sheet, strip, coil |

Alloy EN AW-3003 [Al Mn1Cu]

Welding analysis of 3003 aluminum sheet

The 3003, AL - Mn alloy, is one of the most widely used anti-rust aluminum, this alloy is not high strength, slightly higher than that of industrial pure aluminum, and can not use the heat treatment to make it more strengthen, only the cold working can improve its mechanical properties: in annealing state has high plasticity, in a cold work hardening plasticity is good, when the cold work hardening plasticity is low, good corrosion resistance, good weld-ability, cutting performance is bad. Used for processing need good form-ability, high solder-ability good resistance to corrosion of parts, components, or both require these performance and needs to have more than 1 XXX alloy high strength work, such as kitchen utensils and appliances, food and chemical products processing and storage device, transport liquid product tank, tank, with thin plate processing all kinds of pressure vessel and pipeline.

The package of 3003 aluminum sheet/coil

1. the paper or cover film between aluminum sheet to ensure the surface of the aluminum plate without intact or scratch

2. plastic or paper package to moisture-proof and waterproof, guarantee the aluminum plate clean with no dirt in transit, each package has moisture-proof desiccant.

3. Reinforce the wooden brackets with steel straps to avoid collision during transportation, so as to ensure that the geometry of the aluminum plate is unchanged

4. Fumigation wooden pallet