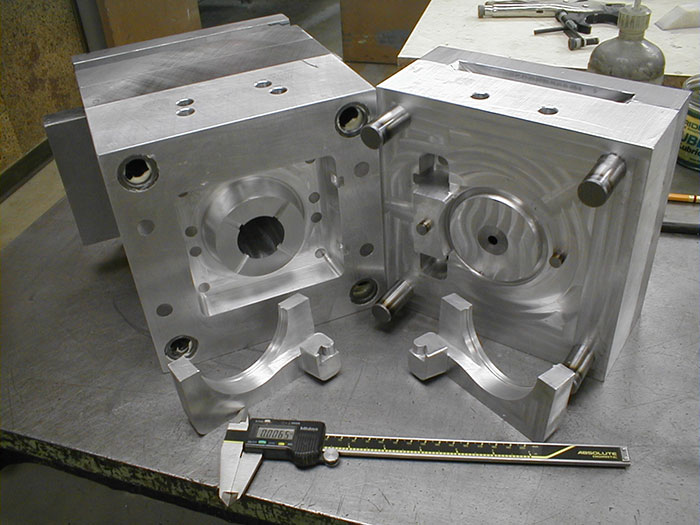

Aluminium molds have many features such as high accuracy, long service life, easy processing, and multiple recycling. They are very popular mold varieties for companies in recent years. In the aluminum plate series, there are mainly 5, 6-series alloys with medium hardness and 2,7-series alloys with high hardness for mold manufacturing. Enterprises can choose according to different needs.

2 series

aluminum mold plate belongs to aluminum copper alloy, the main alloying element is copper element. Copper is an important alloying element and has a solid solution strengthening effect. After adding copper to the aluminum alloy, the aging time is obviously enhanced, and the alloy has a very obvious strengthening effect. The best effect is when the copper content is 4%-6%. .

The 5 series

aluminum mold plate belongs to the aluminum-magnesium alloy. In addition to the unexpected accidents caused by the mold, the aluminum-magnesium alloy is the aluminum plate most commonly used in the automotive industry. Magnesium has a significant strengthening effect on aluminum alloys. For each 1% increase in magnesium, the tensile strength increases by 34 MPa. Aluminum-magnesium alloy has moderate strength, strong plasticity, good weldability and rust resistance.

The 6 series

aluminium mold plate belong to the aluminum-magnesium-silicon alloy, and the main alloying elements are magnesium element and silicon element. The addition of silicon to the alloy allows the aluminum alloy to have excellent castability and corrosion resistance. The aluminum-magnesium-silicon alloy formed in a certain proportion has excellent properties and is the main material for manufacturing high-end precision molds. one.

The 7 series

aluminium mold plate belongs to Al-Zn-Mg alloy, and the main alloying elements are zinc and magnesium. The addition of zinc alone to the alloy has no obvious strengthening effect on the alloy and may cause problems such as stress corrosion cracking; however, the AlZn2 formed by the two elements of zinc and magnesium has a strong strengthening effect on the alloy, and the tensile strength of the alloy. The strength and yield strength increase as the proportion increases. 7 series aluminum plate is also an important material for the aerospace and aerospace industries.