Under the multiple pressures of reducing environmental pollution and fuel economy, automobile weight reduction has been increasingly valued by society and enterprises. According to experiments conducted by international research institutes, if the vehicle's vehicle weight is reduced by 10%, the fuel efficiency can be increased by 6% to 8%; for every 100kg of vehicle's vehicle quality, the fuel consumption per 100km can be reduced by 0.3 to 0.6L. Replacing traditional steel manufacturing cars with aluminum can reduce the weight of the vehicle by 30% to 40%.

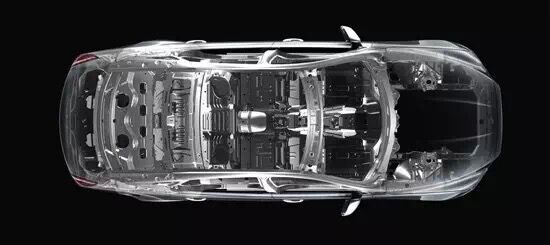

The world-renowned US pure electric vehicle production company Tesla developed and manufactured the Model S entire vehicle containing 250 patents. Its all-aluminum body combines lightweight and high-strength characteristics. In addition to the body, most of its front and rear suspensions are made of aluminum.

At present, the common aluminum plate types for making automobile bodies are

5754 aluminum plate,

6014 aluminum sheet, and

6016 aluminum sheet.

6014 aluminum sheet and

6016 aluminum sheet have good forming performance and bake hardening performance. They are widely used in engine covers, doors, trunk lids, roof covers, etc., and automotive body covers (especially outer plates). They are special materials for automotive aluminum plates.

5754 aluminum plate has a medium strength, good corrosion resistance, weldability and easy processing and forming characteristics, different heat treatment of the

5754 aluminum plate is usually used to make car doors, molds, seals.