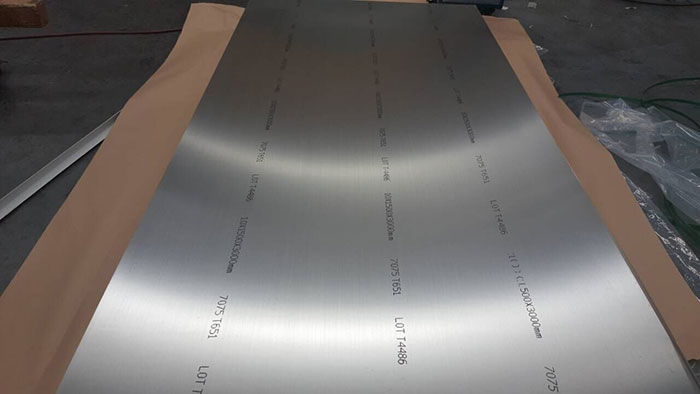

The

7075-T651 aluminum plate is the main structural material in the fields of aviation, aerospace and other fields, and its internal stress is required to be small and uniform. The use of aluminum alloy pre-stretched plates to manufacture aerospace and aerospace aircraft force components greatly reduces processing costs and manufacturing costs, and greatly solves the problem of riveting of large structural components. The main production process of the

7075-T651 aluminum plate is: ingot casting → rolling → solution treatment (quenching) → pre-stretching → aging.

7075-T651 aluminum plate is known as the best product in aluminum alloy. T651 indicates that this alloy has undergone heat treatment and pre-stretching process. T6 and T651 alloys have a tensile strength of 572 MPa and a yield strength of 503 MPa. At the same time, 7075 aluminum alloy has good mechanical properties and anodizing properties.

Features:

High strength heat treatable alloy.

Good mechanical properties.

Usability is good.

Easy to process, good wear resistance.

Corrosion resistance, good oxidation resistance.

We manufacture

7075-T651 aluminum plate with thickness of 6.0mm-250mm, width: 800mm~3800mm, tensile strength: 570mpa, yield strength: 495mpa, elongation: 10%. The company has long-term 7075 T6 aluminum alloy mold plate, can be cut according to customer needs. Super thick plates can be cut into small pieces of aluminium and can be ordered at retail and in small quantities.