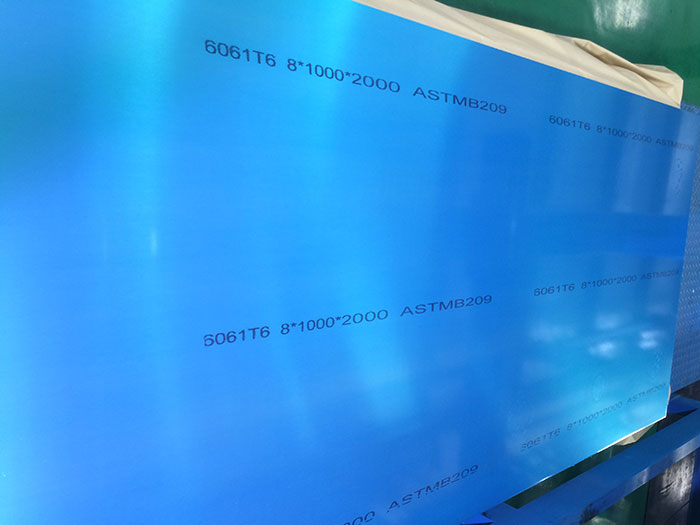

Aluminum plate 6061-t6 is widely used in ships, buildings, vehicles, etc. due to its good corrosion resistance and weldability. The T temper is heat treated. Our company has an advanced 1+1+4 hot rolling production line and uses a hot rolling process to produce

aluminum plate 6061-t6. The following is a brief introduction to the hot rolling production process of aluminum sheets.

The hot rolling is a slab cast into a thickness of 300-500 mm by an aluminum ingot, rolled at a crystallization temperature or higher, and rolled to a product of various thicknesses on a hot rolling facility after heating, (finishing is required later). Many materials require high corrosion resistance, and fatigue resistance, plasticity, etc. all require hot rolling. After hot rolling, more than 90% of the hot deformation process, the internal structure undergoes multiple recrystallization during the plastic deformation process, the coarse crystal grains in the as-cast state are broken, the micro cracks are healed, and the internal structure of the billet is homogenized and crystallized. The casting defects such as the size and shape of the particles, the point defects and the line defect concentration change are all significantly improved, and the as-cast structure is transformed into a deformed structure, which greatly improves the processing performance of the aluminum metal. Especially in the deep drawing performance, hot rolled materials have the incomparable advantages of casting and rolling materials.

Hot rolled product classification:

1. Hot-rolled thick plate: aluminum and aluminum alloy plates with a thickness of not less than 7.0mm. The main varieties are hot-rolled sheets, annealed sheets, quenched or quenched pre-stretched sheets. Hot-rolled slabs are usually produced by a block method on a hot rolling mill. The traditional process is: ingot homogenization - milling - heating - hot rolling - shearing - straightening.

2. Hot rolled coil: Aluminum and aluminum alloy strips with a thickness of less than 7.0mm are usually produced by hot rolling. The products are mainly used as cold rolled billets and also used for producing sheets. The modern production process is: ingot milling Surface - heating <soak heating integration> - hot rough rolling - winding - baling and weighing.

Advantages of

aluminum sheet 6061-t6 hot rolling:

Hot-rolling blanking can weld some defects of the ingot such as looseness, shrinkage cavity and intergranular micro-crack, etc., without causing subsequent processing of internal structural defects, and the grain of the strip is fine and the properties are uniform. hot-rolled

aluminum sheet 6061-t6 has good surface quality, strong mechanical properties and ductility, and good oxidation effect.